- Home›

- Medical Devices›

- Injection Instruments›

- Injection & Precision Instruments›

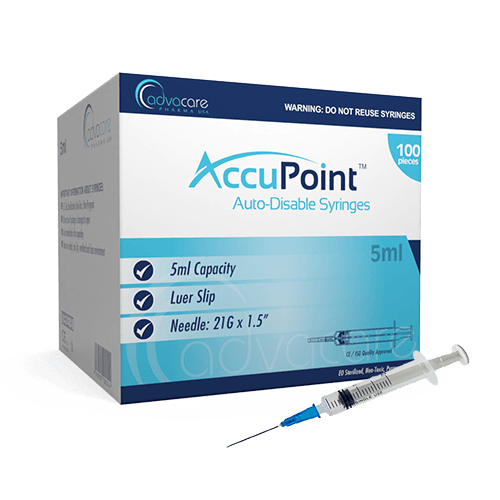

- Auto-Disable Syringes

Auto-Disable Syringes

Tip Type

Needle Size

Capacity

Packaging

What are Auto-Disable Syringes?

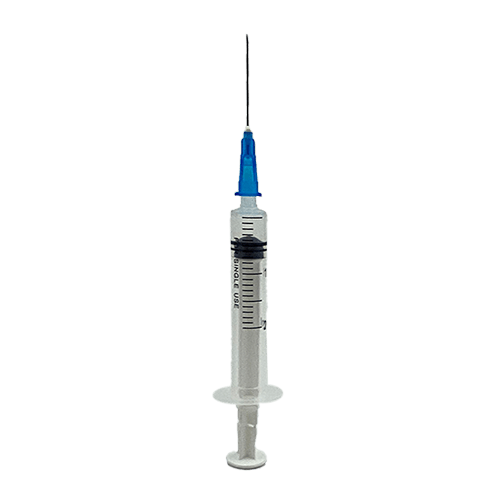

Auto-Disable Syringes are designed to prevent reuse and reduce the transmission of bloodborne pathogens by automatically disabling the plunger after a single use. This safety feature makes them suitable for immunizations and other medical procedures that require a single dose of medication.

Auto-locking syringes eliminate the need for separate needle disposal and reduce the risk of accidental needlestick injuries.

As a global leader in medical device manufacturing, AdvaCare Pharma produces high-quality Auto-Disable Syringes at our facilities in China, India, and the USA. We pride ourselves on our commitment to excellence and our strict adherence to regulatory guidelines to ensure the safety and efficacy of our products.

Product Specifications

Type

Luer Slip configuration enables the needle to be easily pushed onto the tip without twisting it. This type is commonly used for procedures that require a quick and easy needle attachment. This type of connection is generally used for low-pressure applications and can be used with or without a needle.

Luer Lock in auto-disable syringes features a secure screw-type connection that enables the needle to be screwed onto the tip and then securely locked in place. This design helps to ensure that no liquids can leak, thus providing a safe and reliable option for single-use applications.

Why are we a leading Auto-Disable Syringes manufacturer?

AdvaCare Pharma is a global leader in the manufacture of Auto-Disable Syringes, providing high-quality syringes that meet the evolving needs of healthcare professionals.

Our AccuPoint™ brand is produced in ISO and CE-certified facilities with rigorous quality control measures in place to ensure compliance with global health and safety standards. We are committed to innovation and excellence, offering FDA certifications for certain specifications and STED dossiers for all products.

We believe that strong partnerships are key to success, which is why we offer exceptional customer service and support to our medical distributors. Our experienced teams of sales, regulatory and product specialists are available to provide support and answer any questions, and our efficient global distribution network ensures timely delivery of our medical devices.

Uses

How do healthcare professionals utilize Auto-Disable Syringes?

Healthcare professionals engage with Auto-Disable Syringes by adhering to a process that guarantees patient well-being and prevents disease transmission:

- Before any procedure, the practitioner verifies the sterility and integrity of the syringe.

- The subsequent step involves attaching a sterile needle (if not pre-attached), checking it fits securely.

- To maintain accuracy in medication delivery, it is paramount to eliminate any air within the syringe prior to injection.

- Upon administering the medication or vaccine, the syringe's auto-disable feature is activated, preventing further use by locking the plunger. This auto-disable mechanism is a safeguard against the reuse of syringes, mitigating the spread of infections.

- After the procedure, the syringe is immediately disposed of in a puncture-resistant sharps container, adhering to health and safety protocols.

What are the guidelines for disposing of Auto-Disable Syringes?

The disposal of Auto-Disable Syringes involves a structured approach to establish safety and compliance with health regulations. After usage, these syringes are placed directly into designated sharps disposal containers. These containers are specifically engineered to be puncture-resistant and are clearly labeled to differentiate them from other types of waste.

Healthcare environments are tasked with implementing disposal procedures that comply with local and national guidelines. This includes providing accessible sharps containers, educating staff on proper disposal practices, and arranging for the safe collection and transportation of medical waste to designated disposal facilities. Such measures are basic in preventing potential injuries and maintaining a clean, safe environment for both healthcare workers and patients.

How do Auto-Disable Syringes contribute to global health initiatives?

Auto-Disable Syringes are a cornerstone in global health efforts, particularly in vaccination campaigns and efforts to curb the spread of infectious diseases. Their one-time-use design directly addresses concerns related to syringe reuse and improper disposal, which are notable factors in the transmission of diseases.

By locking after a single use, these syringes confirm medications and vaccines are administered safely, aiding large-scale immunization efforts without the risk of cross-contamination or the spread of bloodborne pathogens.

In addition to their safety features, Auto-Disable Syringes are instrumental in achieving high coverage rates in vaccination campaigns, especially in regions where resources are limited, and healthcare infrastructure may be underdeveloped.

Their ease of use and disposal make them an invaluable instrument in efforts to elevate public health, reduce disease incidence, and ultimately save lives on a global scale.

What innovations in Auto-Disable Syringes are shaping the future of healthcare?

Recent advancements in Auto-Disable Syringes are shaping healthcare by focusing on increased safety, user convenience, and environmental sustainability.

Innovations include the development of syringes with more intuitive auto-disable mechanisms that give a clearer indication of when the syringe has been used, reducing the risk of accidental reuse or injury. Research into eco-friendlier materials aims to reduce the environmental impact of these single-use devices without compromising their integrity or functionality.

Technological advancements are also leading to syringes that can deliver medications more efficiently, with minimal discomfort to the patient. These innovations not only prioritize patient and healthcare worker safety but also align with broader public health goals to build on care delivery and outcomes worldwide.

How do Auto-Disable Syringes advance health equity across diverse populations?

Auto-Disable Syringes are central in advancing health equity, offering a universal solution that safeguards patients across various socioeconomic backgrounds. Their deployment in global vaccination initiatives, particularly in under-resourced regions, is a testament to their part in leveling the healthcare playing field.

By providing a reliable means to administer vaccines safely, these syringes are active in reaching population segments that are often at risk of infectious diseases due to limited access to healthcare services.

The design of Auto-Disable Syringes, which prevents reuse and potential contamination, is especially paramount in settings where healthcare practices and waste management systems may not meet stringent standards.

This characteristic guarantees that all individuals, regardless of where they live or their economic status, receive care that adheres to global health safety standards.

Consequently, these syringes are a dominant component in worldwide efforts to eliminate diseases like polio, hepatitis, and measles, contributing considerably to the pursuit of health equity and the well-being of global populations.

How do advancements in Auto-Disable Syringes technology benefit patient care?

Advancements in Auto-Disable Syringes technology are set to revolutionize patient care by enhancing safety, comfort, and efficiency. Innovations such as ultra-fine needles and ergonomic designs minimize patient discomfort during injections, making medical procedures less daunting and more acceptable, especially for children and needle-phobic individuals.

The integration of advanced materials increases the syringe's durability and reliability, introducing precise medication dosage without leaks or breaks.

Emerging technologies also include smarter auto-disable mechanisms that provide clear visual or tactile indicators once the syringe has been used, eliminating any ambiguity about its status.

This feature is valued in high-paced environments like mass vaccination campaigns and emergency medical settings, where speed and safety are paramount.

As these technologies continue to evolve, Auto-Disable Syringes not only contribute to preventing disease transmission but also to upgrade the overall patient experience by making medical procedures safer, quicker, and less stressful.

FAQs

How do Auto-Disable Syringes work?

Auto-disable (AD) syringes have a special mechanism that locks the plunger after a single use, preventing the syringe from being reused and reducing the risk of transmission of bloodborne pathogens.

What is the difference between luer slip and luer lock tip types?

Luer Slip tip type allows the syringe to be easily slipped on and off the needle, while Luer Lock tip type requires the needle to be screwed onto the syringe and locked in place.

What are the different needle sizes available in Auto-Disable Syringes?

Auto-Disable syringes are available in a range of needle sizes from no needle to 25G, allowing for use in a variety of medical procedures.

What are the different capacities available?

Auto-Disable Syringes come in different capacities ranging from 0.1ml to 10ml, making them suitable for a wide range of medical applications.

How should Auto-Disable Syringes be stored and handled?

They should be stored in a cool, dry place, away from direct sunlight, and should not be exposed to extreme temperatures. They should be handled with care and disposed of properly after use in accordance with healthcare waste management guidelines.

How do you ensure the quality of your Auto-Disable Syringes?

We enforce rigorous quality assurance procedures across all stages of production and distribution for our medical devices, bolstered by certifications such as CE, ISO, and/or USFDA, to uphold impeccable standards of quality and safety.

Can I access product specifications and technical documents for your Auto-Disable Syringes?

Yes, we provide access to product specifications and technical documents necessary for product registration and available upon request for distributors and healthcare professionals.

Can I distribute your Auto-Disable Syringes in hospitals, clinics and other medical institutions?

Yes, our medical devices are suitable for distribution in various healthcare settings, including hospitals, clinics, pharmacies, and other medical institutions. With our streamlined distributor verification process, getting started is simple. Reach out to our International Sales Department to learn more about distributing our medical devices in your market.

References

Examining Unsafe Injection Practices Associated with AD Syringes

This systematic review explores concerns about the potential for unsafe injection practices associated with auto-disable (AD) syringes, particularly focusing on the risk of reuse and the transmission of bloodborne pathogens. The review found no evidence linking AD syringe design to such unsafe practices, highlighting the importance of expanding the use of AD syringes in immunization and therapeutic contexts as a critical strategy for reducing the transmission of bloodborne viruses. This evidence supports the continued adoption and innovation of AD syringes to improve global health safety.

Why Auto-Disable Syringes Are Key to Vaccinating the World

This article discusses the vital role of auto-disable syringes in the global vaccination effort, especially highlighted during the COVID-19 pandemic. It emphasizes the challenge posed by a significant shortfall in the supply of these syringes and how manufacturers, like Revital Health Care in Kenya, are ramping up production to meet the demand. AD syringes, designed to prevent reuse and thus reduce the transmission of infections, are essential for safe immunization practices worldwide. The piece also touches on the logistical challenges of matching syringe sizes with vaccine doses, underscoring the need for continued innovation and production to support vaccination campaigns.

You might be interested in...

Why AdvaCare Pharma?

As an industry leader, we are aware of our responsibility to provide affordable and sustainable solutions to improve healthcare worldwide.