- Home›

- Medical Devices›

- Injection Instruments›

- Injection & Precision Instruments›

- Surgical Blades

Surgical Blades

Material

Size

Handle

Packaging

What are Surgical Blades?

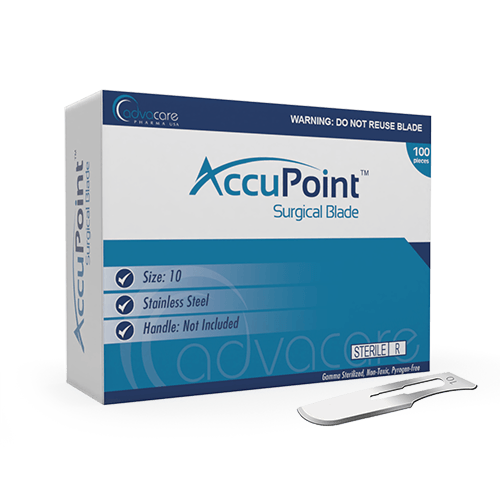

Surgical Blades are sharp, precision cutting medical instruments used by healthcare professionals to perform a variety of surgical incisions in skin, tissue, or bone with accuracy and minimal tissue damage. Available in various sizes, they are made of either stainless or carbon steel and come with or without handles.

Surgical blades are typically disposable and are designed to be used for a single procedure to prevent infection and ensure optimal performance. They are commonly used in a variety of medical specialties, including general surgery, orthopedics, dermatology, and plastic surgery. The selection of the appropriate blade type and size will depend on the specific surgical procedure being performed and the surgeon's preference.

AdvaCare Pharma manufactures high quality stainless steel and carbon steel Surgical Blades at its facilities in the USA, India, and China. Our global production plants regularly undergo extensive inspection and evaluation to ensure compliance with ISO and CE standards, and all safety, health, and environmental protocols.

Product Specifications

Material

Stainless Steel surgical blades have superior anti-corrosion properties, making them an ideal choice for procedures that involve exposure to saline solution or other liquids. They offer a greater level of durability and resistance to rust, ensuring longevity and reliability in demanding medical environments. Moreover, they are well-suited for procedures that require numerous, precise incisions over an extended period of time, as they maintain their sharpness over prolonged use. Given these attributes, stainless steel surgical blades are often preferred for use in disposable scalpels and other medical instruments.

Carbon Steel surgical blades are known for their initial sharpness and durability, making them a preferred option in surgical settings where precision and longevity are paramount. Due to their hardness, they can maintain a sharper edge for longer periods of time compared to stainless steel surgical blades. This makes them ideal for procedures that require a higher level of accuracy, such as fine incisions in soft tissue or bone. Additionally, carbon steel surgical blades are often used for surgical applications that require resistance to bending or breaking.

Handle

Surgical Blades With Handles offer a safe and convenient option for medical professionals. The handles are designed to accommodate blades of different sizes and are made from various materials to suit specific surgical requirements. The handles of surgical blades may also have ergonomic features such as a comfortable grip or a non-slip surface to ensure better control and precision during medical procedures.

Surgical Blades Without Handles provide a versatile option for medical professionals who prefer to use their own handle or need to customize the blade for a specific procedure. Using surgical blades without handles can help reduce waste and cost, as only the blade needs to be replaced after use rather than the entire instrument.

Why are we a trusted Surgical Blades manufacturer?

AdvaCare Pharma is a trusted global supplier and manufacturer of Surgical Blades, which come in various materials, sizes, and handle types. All medical devices under the AccuPoint™ brand are CE and ISO-certified and are accompanied by a STED dossier to give our distributors and partners the confidence from knowing that our medical instruments are manufactured according to the highest standards. At present, we provide medical devices to distributors, hospitals, pharmacies, NGOs, and government institutions in more than 65 markets globally.

We have implemented a vested supplier-distributor relationship to set us apart from any other large scale medical manufacturer with global distribution. Our policies and processes aim to equally share distribution responsibilities and we closely work with our distributors to ensure a mutually beneficial outcome during market entry and market development.

Uses

How should Surgical Blades be used?

Surgical blades should be handled carefully using a blade holder or scalpel handle to avoid injury to the user or patient. The blade should be inserted securely and positioned at the desired angle for the incision. The blade should be used for only one patient and discarded appropriately. Proper sterilization and handling techniques should be followed to prevent infection.

How should Surgical Blades be disposed of?

Used surgical blades should be disposed of in a sharps container immediately after use to prevent injury and infection. The sharps container should be labeled appropriately and disposed of according to local regulations.

FAQs

What is the difference between stainless steel and carbon steel Surgical Blades?

Stainless steel surgical blades are more resistant to corrosion and are less likely to rust compared to carbon steel blades. They also maintain their sharpness for a longer time. On the other hand, carbon steel blades are harder and can hold a sharper edge, but they are more prone to rusting and require more maintenance. The choice between the two types of blades depends on the specific surgical application and the preferences of the surgeon.

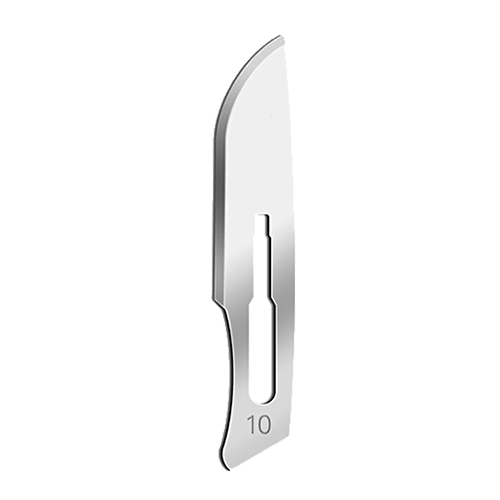

How do the various sizes of Surgical Blades differ from each other?

Surgical blades differ in size based on the length and width of the blade. The blade size also determines the depth and width of the incision made during surgery. The larger the number assigned to the blade, the smaller the size of the blade. For example, a size 10 blade is larger than a size 15 blade.

Can Surgical Blades be reused or are they disposable?

Most surgical blades are designed to be disposable and should not be reused. Reusing incision blades can increase the risk of infection and compromise the integrity of the blade, which can affect its performance. However, some specialty blades may be designed for reuse and can be sterilized between uses.

How are Surgical Blades selected for a procedure?

The choice of surgical blade depends on the specific requirements of the procedure and the preferences of the surgeon or medical professional. It is important to consult with the surgical team and review the procedure instructions to determine the appropriate blade size and type.

How are Surgical Blades packaged for shipping and storage?

Surgical blades are typically packaged in sterile, sealed pouches to ensure that they remain sterile until they are ready to be used. The pouches are often color-coded or labeled to indicate the blade type and size. These pouches are then packaged in boxes or trays for shipping and storage.

How do you facilitate regulatory compliance for importing your Surgical Blades?

Discover our extensive regulatory assistance for distributors, ensuring compliance with local regulations during the importation of our medical devices. With our proficient Regulatory Affairs Department, including pharmacists, biomedical engineers, QA professionals, and documentation specialists, we ensure hassle-free product registration.

You might be interested in...

Why AdvaCare Pharma?

As an industry leader, we are aware of our responsibility to provide affordable and sustainable solutions to improve healthcare worldwide.