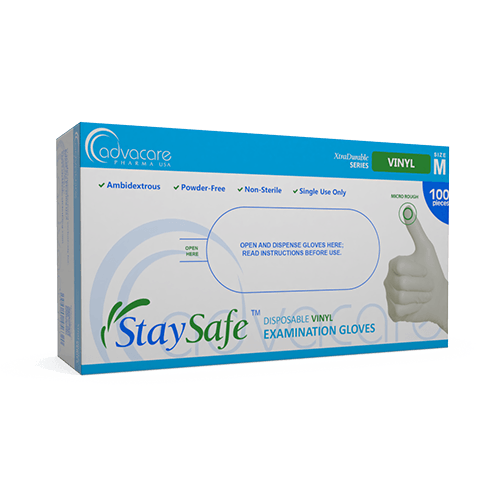

Vinyl Gloves

Material

Surface

Texture

Grade

Size

Packaging

What are Vinyl Gloves?

Vinyl Gloves are disposable gloves used to provide a barrier between the wearer's hands and any potential contaminants. This style of gloves is commonly used in industries such as healthcare, food service, and janitorial work. Vinyl is latex-free, which is an ideal alternative for individuals with latex allergies.

The vinyl examination gloves are available as powdered or powder-free. Powdered gloves have cornstarch added, which makes them easier to put on and take off. Though both powdered and powder-free gloves offer the same level of protection, powder-free vinyl gloves are often preferred by individuals with sensitive skin.

Disposable vinyl gloves can be produced with either a micro-rough or smooth texture and are available in small, medium, large, and extra-large sizes. These medical-grade vinyl gloves have an AQL (Acceptable Quality Level) of ≤ 2.5, which makes them suitable for use in healthcare settings.

Vinyl Gloves are manufactured by AdvaCare Pharma, a reputable pharmaceutical company with expertise in global distribution. This medical disposable product is carefully produced in a CE/ISO-certified facility situated in China, India, and the USA. These facilities are routinely inspected to ensure our products meet health, safety, and environmental standards.

Product Specifications

Material

Surface

Texture

Vinyl

Vinyl gloves are manufactured from vinyl, which is the most economical material and cost-effective option. Vinyl offers a good alternative to latex gloves for individuals with latex allergies.

Vinyl gloves have a relatively low resistance to punctures, and therefore are only suitable for low-risk procedures and tasks, such as patient transportation.

Powdered

Powdered gloves are designed with an interior lining of cornstarch powder, enabling smoother donning and doffing by reducing friction. The powder also helps absorb moisture, ensuring hands stay dry even during extended periods of use.

It is important to note that powdered gloves may not be suitable for individuals with sensitive skin or allergies. Additionally, the presence of powder poses a potential risk of contamination, which makes this style less suitable for certain procedures where contamination control is vital.

Powder-Free

Powder-Free gloves are designed without an inner layer of powder. Powder-free interiors of gloves significantly reduce the risk of allergic reactions while also minimizing potential contamination.

While they may require more effort to put on and take off when compared to powdered gloves, powder-free gloves are highly versatile and considered more eco-friendly.

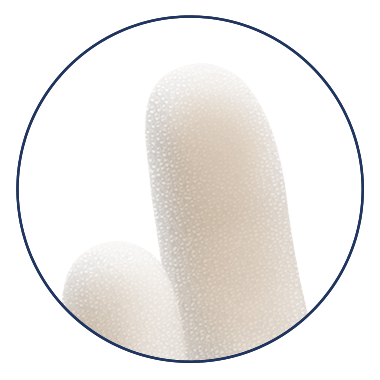

Micro-Rough

Micro-Rough vinyl gloves have micro-textured fingertips and a matte finish for increased grip control without loss of tactile sensitivity.

Micro-rough exam gloves provide a non-slip grip, ensuring reliability even in wet or oily environments. These vinyl gloves are ideal for applications that demand precise handling and secure grip, including medical procedures and laboratory tasks where accuracy is crucial.

Smooth

Smooth vinyl gloves offer a consistent and uniform surface across the entire hand without textured fingertips.

Smooth vinyl exam gloves have a comfortable fit and are easy to put on and take off. This style of vinyl glove is commonly used in a wide range of industries and sectors, including medical and non-medical tasks.

Why choose us as your Vinyl Gloves manufacturer?

AdvaCare Pharma is a leading pharmaceutical company that excels in manufacturing of Vinyl Gloves and other top-tier medical devices for protective use. We prioritize the production of high-quality, cost-effective PPE medical supplies, and our highly-skilled team works with our distributors to deliver customized solutions catering to the unique requirements of each market.

Over the past twenty years, we have established ourselves as a trusted and reliable exporter and manufacturer of Vinyl Gloves and other medical disposables. Our partnerships include distributors, hospitals, pharmacies, and other many other institutions.

Uses

What are Vinyl Gloves used for?

Vinyl gloves are employed to establish a protective barrier for the hands, primarily in medical settings. These gloves are commonly used by medical professionals due to their compliance with AQL ≤ 2.5 (Acceptable Quality Level) standards.

They aid in infection control measures by creating a protective layer between healthcare providers' hands and potential contaminants.

This barrier contributes to maintaining a clean and sterile environment during medical procedures, elevating the safety of both healthcare providers and patients.

What are the storage recommendations for unused Vinyl Gloves?

To preserve the quality of vinyl gloves, follow proper storage practices. Unused vinyl gloves should be stored in a cool, dry, and well-ventilated environment to prevent any adverse effects on their integrity.

Exposure to direct sunlight, heat sources, chemicals, or excessive moisture should be avoided, as these factors can compromise the gloves' performance. Storing vinyl gloves in their original packaging is highly recommended, as it helps prevent potential contamination and preserves their sterility.

Adhering to these storage recommendations guarantees that the gloves remain in ideal condition for use, upholding the highest standards of hygiene and safety.

How should Vinyl Gloves be disposed of after use?

After serving their protective function, vinyl gloves should be disposed of properly to uphold hygiene standards and prevent cross-contamination. The correct disposal procedure involves placing used vinyl gloves into designated waste bins or containers. In medical settings where the risk of exposure to biohazardous materials is a concern, follow local regulations and guidelines for the disposal of such waste.

Specific protocols should be followed when disposing of vinyl gloves that have come into contact with biohazardous substances to prevent the spread of contaminants and aid in the continued safety and cleanliness of the environment.

How are Vinyl Gloves utilized in medical settings?

Vinyl Gloves sustain hygiene and safety efforts in medical settings. Healthcare professionals, including doctors, nurses, and laboratory technicians, use vinyl gloves during various medical procedures to establish a protective barrier between their hands and patients, minimizing the risk of cross-contamination.

These gloves are well-suited for tasks that require frequent glove changes, providing a clean and sterile environment for both medical practitioners and patients.

What makes Vinyl Gloves a suitable choice for healthcare workers with latex allergies?

Vinyl Gloves are an excellent alternative for healthcare workers with latex allergies or sensitivities. Since they are latex-free and do not contain natural rubber latex proteins, they eliminate the risk of allergic reactions.

This makes them a safe choice for medical professionals who need reliable hand protection without the concern of latex-related allergies or skin irritations.

How do Vinyl Gloves contribute to infection control in healthcare facilities?

Vinyl Gloves contribute to infection control within healthcare facilities by acting as a barrier against pathogens and contaminants, reducing the chances of disease transmission between healthcare providers and patients.

Their use is mandatory in preventing the spread of infections in hospitals, clinics, and laboratories, creating a safer and more hygienic healthcare environment.

What are the storage recommendations for unused Vinyl Gloves in medical settings?

To keep the quality and integrity of unused Vinyl Gloves in medical settings, store them appropriately. These gloves should be kept in a cool, dry, and well-ventilated area.

Protecting them from direct sunlight, heat sources, chemicals, and moisture is imperative to prevent any compromise in their efficacy. Storing Vinyl Gloves in their original packaging is recommended to safeguard against contamination and maintain their sterility.

Why choose vinyl gloves over other materials for specific applications?

Vinyl gloves offer distinct advantages over other materials in certain applications:

- They are latex-free, making them an excellent choice for individuals with latex allergies or sensitivities.

- Vinyl gloves are often more budget-friendly, providing a cost-effective option without compromising on basic hand protection.

- Their looser fit can be more comfortable for those who find tight-fitting gloves restrictive. This relaxed fit is particularly beneficial in situations where users need to wear gloves for extended periods.

- While they may not offer the same level of durability as some alternatives, vinyl gloves serve as a practical solution for low-risk procedures and tasks, making them suitable for various industries, including healthcare, food service, and janitorial work.

The choice of vinyl gloves over other materials depends on the specific requirements of the task and the preferences of the users.

FAQs

Can Vinyl Gloves be used for medical purposes?

Vinyl gloves with an AQL of ≤ 2.5 are suitable for medical use. They offer basic protection and are suitable for situations where frequent glove changes are required.

What are the benefits of Vinyl Gloves compared to other materials?

Vinyl gloves are a suitable alternative for individuals with latex allergies or sensitivities as they do not contain natural rubber latex proteins. They are typically a budget-friendly option. Moreover, vinyl gloves are often looser-fitting, which provides a more relaxed fit compared to other types of gloves. This fit can be beneficial for those who find tighter gloves uncomfortable or restrictive.

Should powdered or powder-free Vinyl Gloves be used?

Powder-free gloves are preferred in healthcare settings as there is a risk of powder contamination complications, such as allergies and respiratory issues.

Which texture of Vinyl Gloves should be used?

The choice of texture for vinyl gloves depends on the specific requirements of the task. Smooth vinyl gloves are suitable for tasks that do not require a firm grip or where tactile sensitivity is important. The micro-rough fingertips provide a better grip compared to smooth vinyl gloves.

What types of medical devices does your company manufacture?

We produce a diverse range of over 500 Class I and Class II medical devices, spanning surgical instruments, diagnostic tools, medical consumables, wound care items, and urological equipment to meet the clinical needs of healthcare providers across the hospital, clinic and pharmacy sectors.

References

An Overview of Protective Gloves with Regards to Hand Performance and the Evaluation Methods by F Zare Bidoki, N Ezazshahabi, F Mousazadegan, and colleagues (2021)

This study discusses the impact of wearing protective gloves on hand dexterity and performance, recommending alternatives over vinyl gloves for certain applications. The study is accessible here: Read more.

Can medical-grade gloves provide protection after repeated disinfection? by E Esmizadeh, BP Chang, D Jubinville, and colleagues (2020)

This study examines the durability and protective capabilities of both nitrile and vinyl gloves upon exposure to disinfection processes, highlighting the importance of glove material in ensuring hand protection. The study can be found here: Read more.

Allergic contact dermatitis to rubber accelerators in protective gloves: Problems, challenges, and solutions for occupational skin protection by A Hansen, R Brans, F Sonsmann (2021)

This article discusses potential allergic reactions and the challenges faced by individuals using protective gloves made of materials like vinyl, which may not be suitable for all users due to health concerns. Read more.

You might be interested in...

Why AdvaCare Pharma?

As an industry leader, we are aware of our responsibility to provide affordable and sustainable solutions to improve healthcare worldwide.