- Home›

- Medical Devices›

- Skin & Wound Care›

- Wound Closure Instruments›

- Non-Absorbable Sutures

Non-Absorbable Sutures

Material

Type

Color

Needle

Needle Point Type

Needle Shape

Needle Length

Suture Diameter

Suture Length

Packaging

What are Non-Absorbable Sutures?

Non-Absorbable Sutures are surgical threads that are not naturally broken down by the body and require manual removal after the healing process. Non-absorbable threads are commonly made of materials such as nylon, silk, polyester, or polypropylene, and are ideal for situations where long-term wound support is required.

Non-absorbable sutures provide long-lasting support to wounds and are often used in areas where the tension on the sutures is high, such as in the closure of deep tissue layers or in certain orthopedic procedures. Their durability allows them to remain in place for an extended period, providing stability and promoting proper healing.

The different types of non-absorbable sutures offer varying characteristics that make them suitable for specific applications. Nylon sutures, for example, are known for their high tensile strength and resistance to stretching, making them ideal for wound closure in areas that experience significant stress or movement. Silk sutures are valued for their smooth passage through tissues and excellent handling properties, while polyester and polypropylene sutures offer excellent elasticity and flexibility, allowing for easy knot tying and secure wound closure.

Nylon sutures, such as Ethilon™ sutures, are a popular choice in surgical procedures that require long-term wound support. Known for their excellent handling properties and smooth passage through tissues, Ethilon™ sutures provide reliable and secure wound closure. These sutures are made of high-quality nylon material and are commonly used in a variety of surgical specialties, including general surgery, plastic surgery, and dermatology. The versatility and strength of these sutures make them a trusted option for wound closure.

Polypropylene sutures, such as Prolene™ sutures, offer unique advantages in surgical applications that require long-lasting support. These sutures, made of high-quality polypropylene material, are known for their excellent tensile strength and resistance to stretching. They provide reliable wound closure in areas that experience high tension or movement. Prolene™ sutures are commonly used in cardiovascular, orthopedic, and ophthalmic surgeries, where long-term wound support is crucial. With their excellent handling characteristics and reliable performance, these sutures are favored by surgeons for their ability to ensure secure wound closure and promote proper healing.

AdvaCare Pharma is the trusted source for Non-Absorbable Sutures. We offer a wide variety of products to meet your needs, and we are committed to providing you with the highest quality and safety. Our production facilities are ISO and CE certified, and we adhere to all healthcare and regulatory guidelines. Regular inspections are conducted to ensure the consistent availability of dependable medical supplies.

Disclaimer: AdvaCare Pharma is not the owner of the brand names Prolene™ and Ethilon™. The use of these brand names is for illustrative purposes only and does not imply endorsement or affiliation.

Product Specifications

Material

Type

Needle Type

Needle Shape

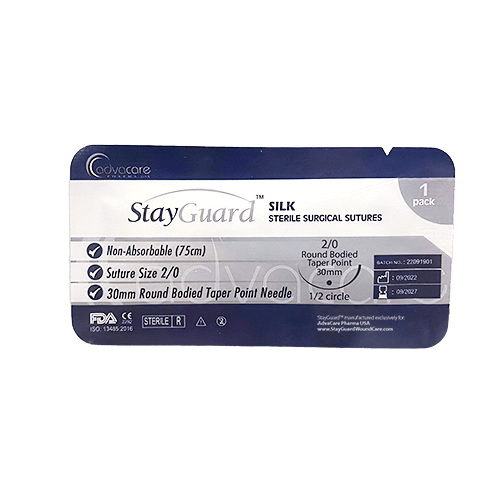

Silk

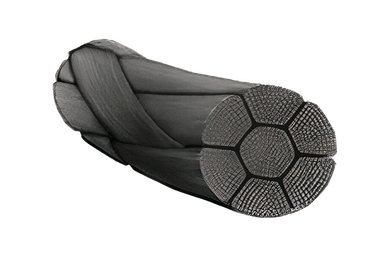

Silk sutures are non-absorbable surgical threads made from natural silk. They have a braided structure and are available in black, blue, or undyed colors. With needle lengths ranging from 13mm to 50mm and suture lengths of 45cm, 75cm, 90cm, and 150cm, they offer flexibility in various surgical procedures. These sterile sutures are contraindicated in patients with a known sensitivity or allergy to silk, ensuring patient safety during wound closure.

Silk sutures, known for their biocompatibility and ease of handling, have been a staple in surgical practice for decades. Their braided structure provides excellent knot security and resistance to breakage, ensuring reliable wound closure. The availability of silk sutures in different colors allows for easy identification during follow-up examinations, facilitating efficient monitoring of the healing process.

Nylon (Polyamide)

Nylon (Polyamide) sutures are non-absorbable surgical threads made from synthetic materials. They have a monofilament structure and are available in black and blue colors. With needle lengths ranging from 13mm to 50mm and suture lengths of 45cm, 75cm, 90cm, and 150cm, they offer versatility in various surgical procedures. These sterile polyamide sutures provide reliable wound closure and are commonly used due to their strength and durability.

Nylon sutures, crafted from synthetic materials, have gained widespread popularity in surgical applications. Their monofilament structure ensures smooth passage through tissues, reducing tissue trauma and the risk of bacterial wicking along the suture line. The availability of nylon sutures in black and blue colors offers enhanced visibility during surgery, allowing for precise placement and improved surgical outcomes. Additionally, the exceptional strength and durability of nylon sutures make them ideal for procedures that require long-term tissue support.

Polypropylene

Polypropylene sutures are non-absorbable surgical threads made from synthetic materials. They have a monofilament structure and come in a distinctive blue color. With needle lengths ranging from 13mm to 50mm and suture lengths of 45cm, 75cm, 90cm, and 150cm, they offer flexibility for various surgical applications. These sterile sutures provide reliable wound closure and are commonly used due to their strength and resistance to degradation. Their synthetic composition ensures long-lasting support and minimal tissue reactivity.

The monofilament structure of polypropylene sutures allows for smooth tissue passage, minimizing trauma and reducing the risk of suture-related complications. The distinctive blue color of polypropylene sutures aids in visibility and differentiation during surgery, enabling surgeons to work with precision and accuracy. Moreover, the non-absorbable nature of polypropylene sutures ensures long-term wound support, making them ideal for applications where extended tensile strength and reliable closure are essential, such as in cardiovascular or hernia surgeries.

Polyester

Polyester sutures are non-absorbable surgical threads made from synthetic materials. They have a braided structure and are available in either green or white color options. With needle lengths ranging from 13mm to 50mm and suture lengths of 45cm, 75cm, 90cm, and 150cm, they provide versatility for different surgical procedures. These sterile sutures offer reliable wound closure and are known for their strength and durability. The synthetic composition of polyester ensures long-term support and minimal tissue reactivity, making them a suitable choice for various surgical applications.

Stainless Steel

Stainless Steel sutures are non-absorbable surgical threads made from synthetic materials. They feature a monofilament structure and come in a silver color. With needle lengths ranging from 13mm to 50mm and suture lengths of 45cm, 75cm, 90cm, and 150cm, they provide flexibility for different surgical needs. These sterile sutures are known for their strength and durability, offering reliable wound closure. The stainless steel composition ensures long-term support and resistance to corrosion.

Non-Absorbable

Non-Absorbable sutures are resistant to biological degradation and are not absorbed by the body. They are commonly used to close the skin, ensuring that the sutures remain intact for an extended period until the wound has fully healed and regained its strength. These sutures should be removed by a healthcare professional once the wound has healed sufficiently and the sutures are no longer needed, promoting proper wound healing and minimizing the risk of complications.

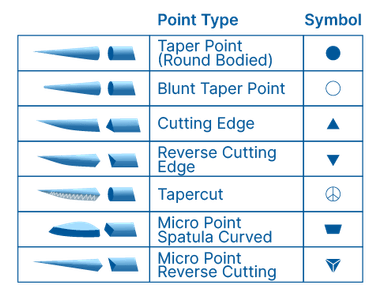

The choice of needle type and shape is crucial when selecting non-absorbable sutures for surgical procedures. Each needle features a sharp point for precise penetration, and some may have sharp sides or spatula-shaped tips for cutting or dissecting and holding tissue planes. Identifying the blunt side of the needle is essential to prevent unintentional tissue dissection. Visualizing the needle's point, tip, and the orientation of its blunt and sharp sides can be aided by referring to the accompanying image. Optimal needle selection is vital to minimize tissue trauma and promote effective wound healing.

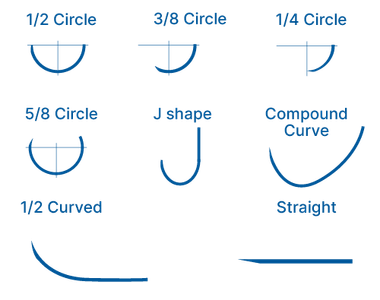

The shape of the needle in non-absorbable sutures is designed to accommodate various surgical needs. Needles with larger curvatures are ideal for navigating narrow surgical fields, ensuring the precise isolation of delicate tissues while minimizing damage to neighboring structures. Smaller curvatures are well-suited for making shallow passes, while longer needles offer enhanced control and the ability to grip more tissue. Surgeons have the freedom to choose the most suitable needle shape based on their preferences and the specific requirements of each surgical technique, as multiple needle types can be successfully employed to achieve optimal outcomes.

Why are we a trusted Non-Absorbable Sutures manufacturer?

With a track record spanning more than 20 years, AdvaCare Pharma is a trusted manufacturer of Non-Absorbable Sutures and other high-quality medical supplies for wound closure. Our extensive network of partnerships with distributors, hospitals, clinics, NGOs, and pharmacies in 65 markets demonstrates our commitment to serving diverse communities.

At AdvaCare Pharma, we are dedicated to manufacturing surgical sutures, including silk, nylon, polypropylene, polyester and other types of non-absorbable sutures, that are CE and ISO-certified while remaining cost-effective for medical institutions. Through our StayGuard™ line of skin and wound care products, we strive to contribute to the well-being of patients worldwide with our comprehensive range of non-absorbable sutures manufactured by AdvaCare Pharma.

Uses

How should Non-Absorbable Sutures be used?

To use non-absorbable sutures:

- First ensure a sterile environment and gather the necessary instruments.

- Hold the needle holder firmly and grasp the suture needle near its midpoint.

- Insert the needle into the tissue, maintaining the appropriate angle and depth based on the specific wound and tissue type.

- Pull the needle through the tissue until the suture material is evenly distributed on both sides of the wound.

- Use the needle holder to tie a knot, ensuring it is secure but not overly tight.

Repeat the process for additional sutures as needed, maintaining proper spacing and tension for optimal wound closure. Once all sutures are in place, trim the excess suture material, leaving an appropriate length for easy removal. Clean and dress the wound according to medical guidelines and provide any necessary post-operative instructions to the patient.

What happens after the surgical procedure?

Regularly monitor the wound for healing progress and consult with a healthcare professional for any concerns or complications.

Non-absorbable sutures will require removal at a later time, typically based on the type and location of the wound.

When should Non-Absorbable Sutures be used instead of absorbable sutures?

Non-absorbable sutures are utilized in scenarios where prolonged wound support or permanent closure is required. Here are some instances where non-absorbable sutures are preferred over absorbable sutures:

- Skin Closure: Non-absorbable sutures are commonly used for skin closure in procedures where the sutures will remain in place for an extended period, such as in cosmetic surgeries, plastic surgeries, or wound closures where meticulous wound approximation is essential.

- Tension-bearing Areas: In surgical sites subjected to significant tension or stress during the healing process, such as in orthopedic procedures or repairs of tendons and ligaments, non-absorbable sutures provide long-term strength and stability to withstand mechanical forces.

- Delayed Wound Healing: In cases where wound healing may be delayed or compromised, non-absorbable sutures offer durable support to ensure optimal wound closure and minimize the risk of wound dehiscence or breakdown.

- Tissue Approximation: Non-absorbable sutures are preferred for joining tissues or organs that require permanent approximation, such as in gastrointestinal surgeries, vascular anastomoses, or closure of fascial layers where long-term structural integrity is necessary.

- Wound Revision: Non-absorbable sutures are used in procedures requiring wound revision or exploration, as they allow for easy removal without causing tissue trauma or disruption of the healing process.

- Allergy Concerns: In patients with known allergies or sensitivities to absorbable suture materials, non-absorbable sutures provide a safe alternative for wound closure, minimizing the risk of adverse reactions or complications.

FAQs

What is the advantage of using Non-Absorbable Sutures?

Non-absorbable sutures provide long-term wound support and do not break down naturally, allowing for sustained closure of surgical incisions or wounds.

How long do Non-Absorbable Sutures remain in the body?

Non-absorbable sutures require manual removal after the healing process is complete, typically ranging from several days to several weeks, depending on the specific suture material and the type of wound.

Can Non-Absorbable Sutures cause any complications?

In rare cases, non-absorbable sutures may cause an inflammatory response or tissue reaction, which can lead to complications such as infection, delayed wound healing, or excessive scarring. It is important to follow proper wound care instructions and seek medical attention if any signs of complications arise.

How are Non-Absorbable Sutures removed?

Non-absorbable sutures are typically removed by a healthcare professional using sterile instruments. The procedure is usually quick and relatively painless, with minimal discomfort.

Can Non-Absorbable Sutures be used on all types of wounds?

Non-absorbable sutures are suitable for a wide range of wounds and surgical procedures. However, certain factors such as wound location, tension, and the patient's overall health may influence the choice of suture material. Consulting with a healthcare professional is essential to determine the most appropriate suture type for a specific wound or surgical intervention.

How do you ensure the quality of your Non-Absorbable Sutures?

We maintain stringent quality assurance protocols throughout the production and entire lifecycle of our surgical sutures, incorporating certifications such as CE, ISO, and/or USFDA to uphold the utmost standards of quality and safety.

Can I access product specifications and technical documents for your Non-Absorbable Sutures?

Yes, product specifications and technical documents for our surgical sutures are available for product registration purposes and/or upon request for distributors and healthcare professionals.

Is regulatory support available for importing your Non-Absorbable Sutures?

Yes, we extend regulatory support and guidance to our distributors, aiding in adherence to local regulations and facilitating the smooth importation of our surgical sutures. Backed by our proficient Regulatory Affairs Department, comprising experts such as pharmacists, biomedical engineers, QA professionals, and documentation specialists, we ensure a seamless product registration process.

Is marketing assistance available for distributors of your Non-Absorbable Sutures?

Absolutely! We offer comprehensive marketing support and resources to empower distributors in promoting our surgical sutures, enhancing brand visibility, and ensuring successful product distribution in their target markets.

References

Absorbable vs non absorbable sutures for wound closure. Systematic review of systematic reviews

This review article compared absorbable and non-absorbable sutures for wound closure, highlighting that absorbable sutures are not superior to non-absorbable sutures in terms of surgical site infections and post-operative outcomes.

Comparison of 10-0 polypropylene and 10-0 nylon sutures in rat arterial anastomosis

This study compares the efficacy of 10-0 polypropylene and 10-0 nylon sutures in rat arterial anastomosis. The study found that both sutures had similar tensile strength and bursting pressure, suggesting that they can be used interchangeably in arterial anastomosis. The 10-0 polypropylene suture had a higher suture-to-artery diameter ratio, which may make it easier to handle and manipulate during the anastomosis process. This study provides valuable insights into the use of 10-0 sutures in microvascular surgery.

You might be interested in...

Why AdvaCare Pharma?

As an industry leader, we are aware of our responsibility to provide affordable and sustainable solutions to improve healthcare worldwide.